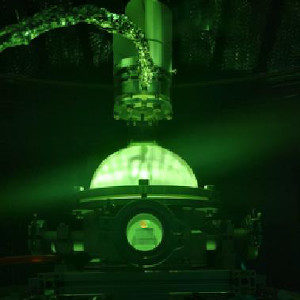

Le laboratoire PROMES est une Unité Propre du CNRS (UPR 8521) rattachée à l’Institut des Sciences de l’Ingénierie et des Systèmes (CNRS Ingénierie) conventionnée avec l’université de Perpignan via Domitia (UPVD). Le laboratoire est localisé sur trois sites : Odeillo-Font Romeu (Four solaire de 1 MW du CNRS), Targassonne (Thémis, centrale à tour de 5 MW, site du Conseil Départemental des PO) et Perpignan, Tecnosud.

Thématiques scientifiques

MEE

Matériaux pour l’Energie et l’Espace

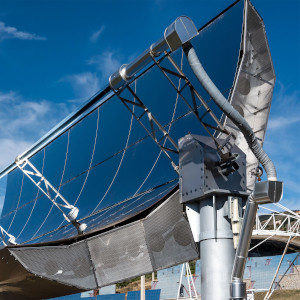

CSPG

Centrales Solaires de Prochaines Générations

SCS

Stockage et Chimie Solaire

A la Une

Les visites insolites du CNRS

4e édition – 6 octobre 2023 – Comment stocker de l’énergie solaire ? Comment la transporter ? Est-ce que les matériaux des sondes spatiales résistent à une entrée rapide dans…

Stockage de la chaleur et du froid

Parution du livre « Stockage de la chaleur et du froid » 1 et 2 aux Edition ISTE – avec les contributions de Régis Olivès, Maxime Perier-Muzet et Driss Stitou. Stockage de…

En vidéos

Four Solaire d’Odeillo vu du Tour de France 2021